GLOBE VALVES

Application: Globe valve straight pattern can be applied on all pipes and plant with non-aggressive fluids for body materials listed in list of materials. Materials listed in list of materials as specified in European standards, and for them pressure/temperature rating are according to EN 12516-1 standard. Globe valve can be operated with handwheel and with other operating devices, as is electric, hydraulic or pneumatic actuator.

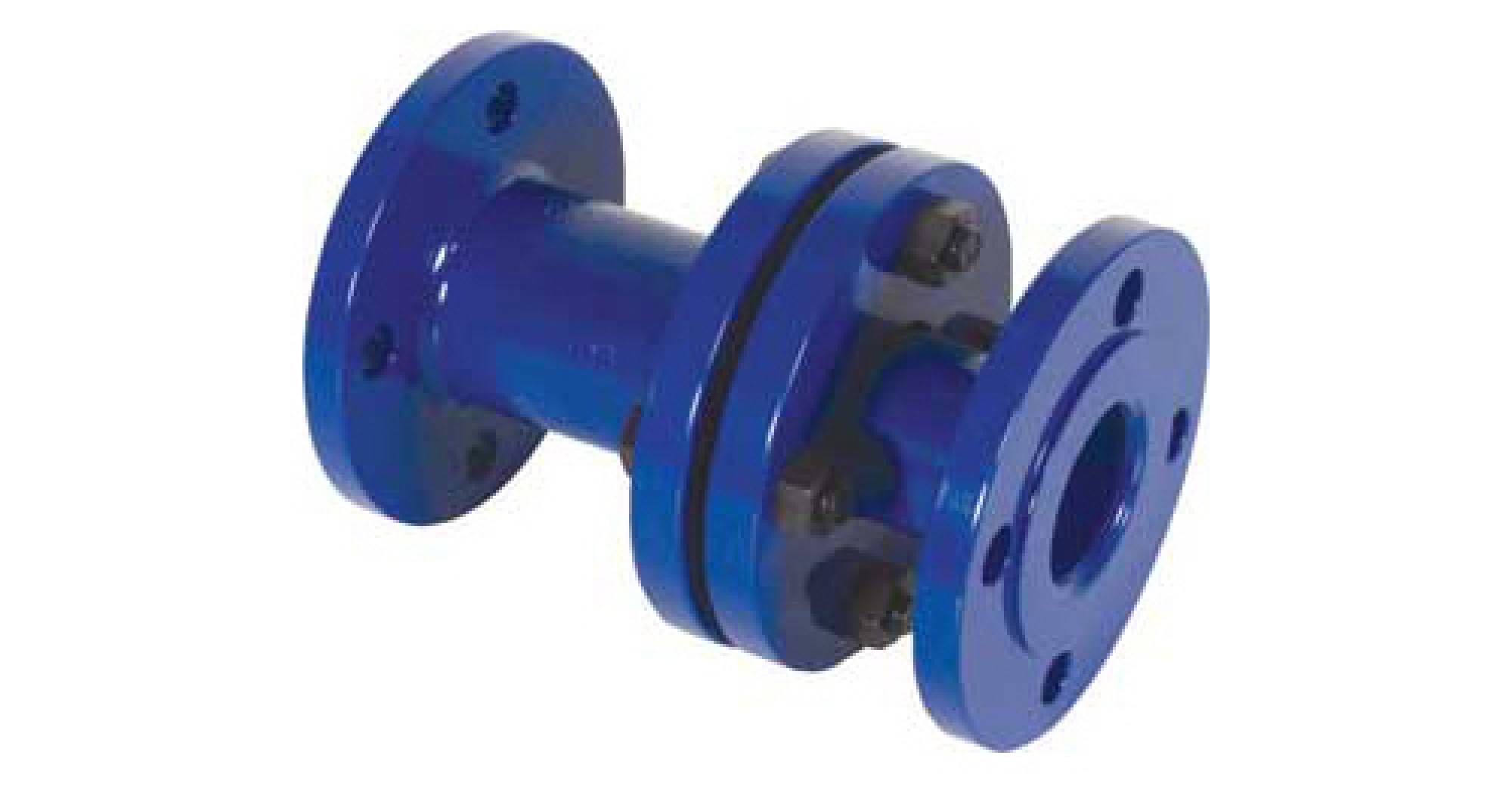

Construction: Globe valve have construction, which satisfy request of the newest actual world norms and standards. Valve body is consisted of body and bonnet, connected with bolts, for smaller dimensions from forged steel and for bigger dimension from cast steel. Valve manipulation is accomplished with axial movement of threaded stem with outside screw and yoke bushing. Connections can be made by flanged or with butt welding ends. Disc is made as separate part, connection with stem is safe, but with possibility for slightly position adjustment. When servicing this connection can be detached.